Improve product quality and reduce costs through technology application in Industry 4.0

In the 4th industrial revolution, digital technology plays a central role, helping businesses improve product quality, reduce costs and increase productivity.

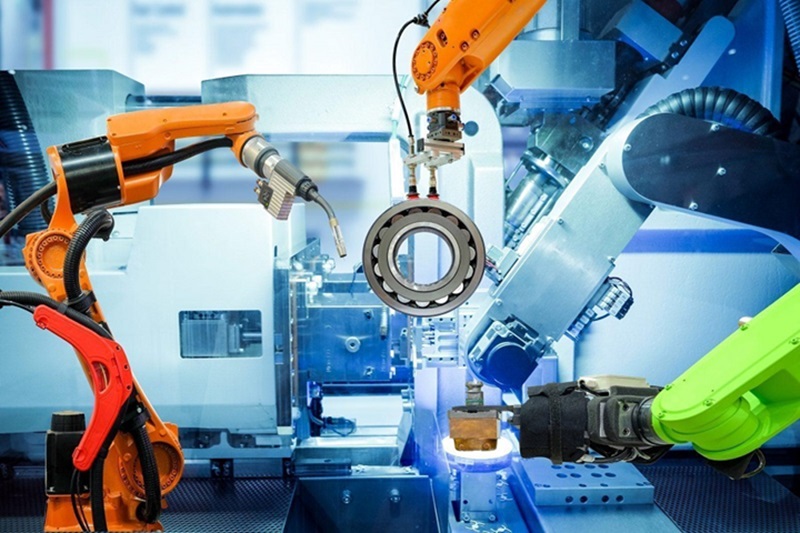

Automatic robots bring many breakthrough changes to life. (Illustration photo)

Sensor systems, machinery and information technology are integrated and connected via Internet-based protocols to continuously exchange data. As a result, businesses can predict, self-adjust and quickly adapt to changes in the market and customers, promoting more efficient production and stronger global competitiveness.

Major technology trends, such as big data analytics, autonomous robots and the Internet of Things (IoT) are all contributing to a dramatic change in the way businesses operate. Big data analytics helps optimize quality, save energy and improve services based on real-time data. Autonomous robots, integrating many fields, such as mechanics, artificial intelligence and sensors, create advanced technology platforms to support production and life. Meanwhile, IoT enables comprehensive control and monitoring of production equipment and processes, while enhancing user convenience through smart home devices and remote-control applications.

Overall, digital technology in the Industrial Revolution 4.0 helps businesses collect and analyze data more quickly and flexibly, thereby optimizing production and business processes. As a result, products and goods can achieve higher quality, reduce production costs, contribute to improving productivity, promoting sustainable growth and enhancing the country's competitive position in the international market.